Silver Diamond Engine

The International Harvester “Silver Diamond” 220 Engine

(Source: International Light Duty Trucks, International Harvester Co., Publication CR-485-C)

Proved SILVER DIAMOND Engine features new performance, new economy

The famous International Silver Diamond 220 engine is built by International Harvester in the largest exclusive truck engine plant in the world.

This six-cylinder, valve-in-head truck engine is an outstanding product of advanced engineering development. It has many new features and improvements designed to give you more power for starting, more power for smoother accelerating, more power for climbing steep grades and hauling heavy loads long distances. Its quick-starting, smooth-running performance combines plenty of highway speed and lugging power with economy and a big reserve of stamina. The Silver Diamond engine is engineered to stand up under years of hard work.

New stellite-faced slo-roto exhaust valves rotate during operation, actually dean themselves in use. Exhaust-valve seats are of long-lasting durachrome, a high chrome-nickel content metal that insures more efficient valve operation for a longer period of time. Carburetion is new too; the visible-flow carburetor featuring a fast-idle cam that speeds engine warm-up, contributes to greater fuel economy.

Other outstanding features of the Silver Diamond 220 engine include: a new ceramic-filter fuel pump engineered to prevent vapor lock; hotter spark plugs to minimize carbon formation; a wide-lobe camshaft that lengthens the life of camshaft and tappets, and a capsule-type thermostat that is unaffected by water pressure, assuring faster engine warm-up and positive maintenance of proper operating temperature.

The Silver Diamond 220 engine develops 100 maximum brake h.p. at 3,600 r.p.m., 90 net h.p. at 3,600 r.p.m.; maximum torque of 173.5 pound-feet at 2,000 r.p.m., net torque of 167 pound-feet at 1,200 r.p.m. Compression ratio is 6.5.

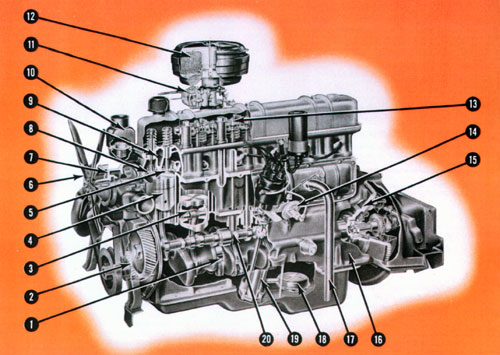

- Precision-type, replaceable main bearings have large bearing area for long life. Heavy, heat-treated crankshaft statically and dynamically balanced.

- Precision-engineered, long-lasting timing gears.

-

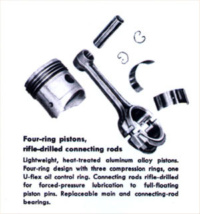

Connecting rods, with big bearing area, rifle-drilled for full-pressure lubrication to full-floating piston pins.

- Thick-dome, T-slot aluminum alloy four-ring pistons with U-flex oil rings.

- Precision-machined combustion chambers assure maximum combustion uniformity and thermal efficiency.

- Big air-flow fan draws full blast through large radiator cooling surface.

- Large-capacity, mechanically sealed, ball-bearing water pump steps up efficiency of cooling system.

- Heat-treated, long-wearing alloy, exhaust-valve seat inserts.

- Streamlined valve ports and cylinder jackets designed for maximum heat dissipation.

- Capsule-type thermostat regulates water flow to speed engine warm-up; maintains uniform temperature for efficient, economical operation.

- New visible-flow carburetor with fast-idle cam. Simplified construction provides more efficient, economical operation.

- Oversize, oil-bath type air cleaner.

-

Rocker arms and tappers designed to provide proper lubrication to valve stems and push rods and to assure quiet operation. New stellite-faced slo-roto exhaust valves rotate slowly, actually clean themselves during operation.

- Full-automated ingnition selector.

- New 10-inch, single-plate, vibration-dampened clutch. New cushioned disc and fgacing for long life, smooth operation. Low pedal pressure.

- Crankcase has extended skirt for extra stregth and rigidity.

- Crankcase ventilator drains off sludge-forming fumes and water vapor, prevents corrosion.

- Floating, screened oil intake ensures “clean level” oil supply.

- Full-pressure lubrication system with large capacity, self-priming pump.

- Induction-hardened, wide-lobe camshaft with extra-large bearing area.